Electronics Manufacturing Services

Comprehensive Electronics Manufacturing Solutions for Design, Production, Assembly, Logistics, and More

Discover ETS electronics manufacturing services capabilities with tailored solutions to meet your project needs. From concept to delivery, ETS ensures precision and quality at every step of your electronics production process.

ETS: Your Next Electronics Manufacturing Services Provider

At ETS, we offer a comprehensive Electronics Manufacturing Services (EMS) solution that encompasses every stage of the product lifecycle—from initial design to final logistics. Our full-service approach ensures that your electronics are developed, manufactured, and delivered with the highest level of quality and efficiency.

What’s the Difference between ECM and EMS?

EMS offers a comprehensive, end-to-end solution that covers the entire product lifecycle—from initial design and development to manufacturing, testing, and logistics. This full-service approach ensures that all aspects of product creation are managed under one roof. On the other hand, ECM focuses specifically on the production phase. Clients come to ECM providers with ready designs and rely on them to manufacture and assemble the products. While ECM is ideal for businesses that already have a developed design and need efficient production, EMS provides a holistic approach, handling everything from concept to final delivery.

Learn more about the differences by clicking the button below.

Manufacture with ETS Today!

Partner with ETS for comprehensive Electronics Manufacturing Services that cover every stage of your product’s journey. Our end-to-end solutions, experienced team, and advanced technologies ensure your products are developed, manufactured, and delivered with excellence.

Discover how ETS can help you transform your designs into exceptional finished products ready to make an impact in your industry.

Comprehensive List of Our Electronics Manufacturing Services

ETS Electronics Manufacturing Services: From Concept to Completion

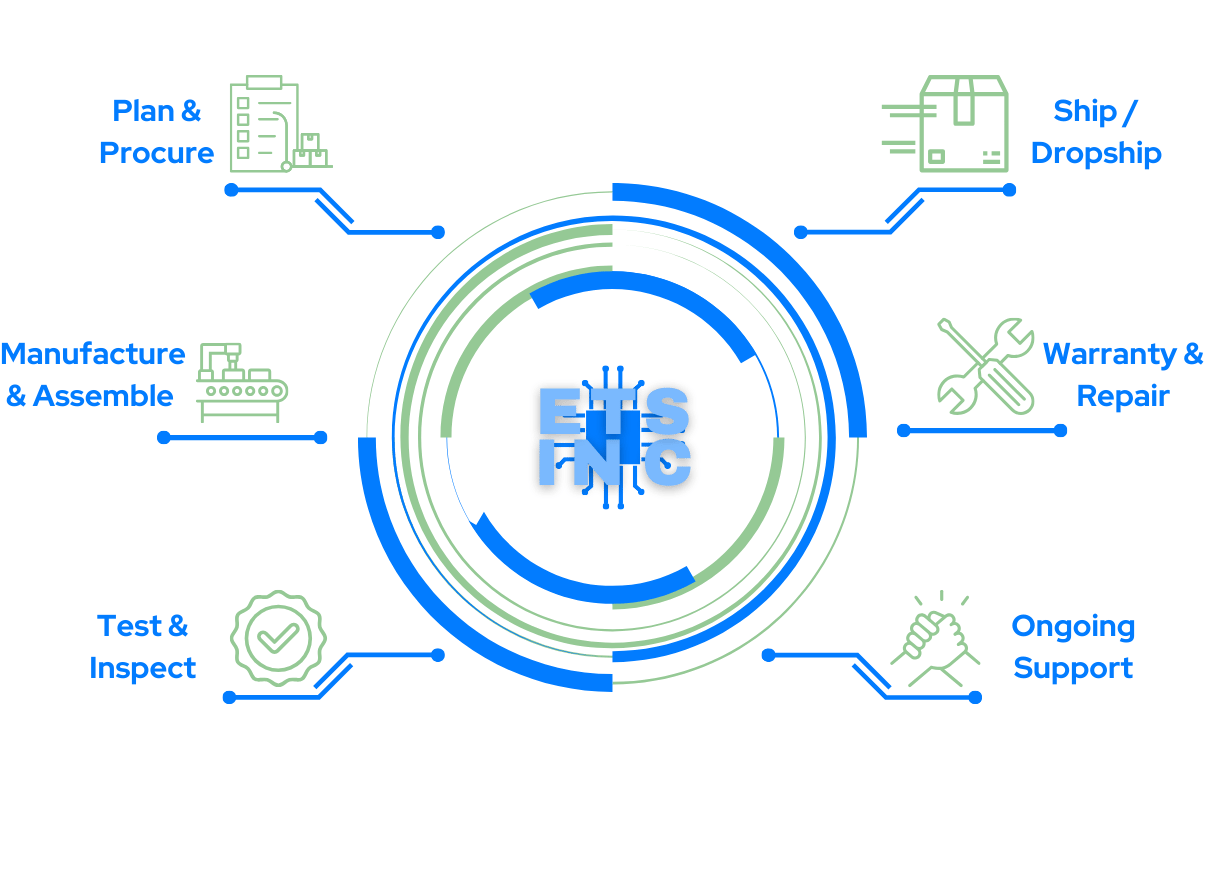

At ETS, we offer comprehensive electronics manufacturing services designed to take your ideas from initial concepts to final, high-quality products. Our approach is divided into two crucial cycles: the development cycle and the production cycle. Each cycle is tailored to meet your specific needs, whether you are starting from scratch with a new idea or looking for efficient, reliable production.

The Development Cycle

The first cycle focuses on turning your product idea into a functional design ready for prototyping and eventual manufacturing. This process involves several key stages:

- Concept

Have a product idea but lack the background in electronic design or time to figure out its feasibility? Share your concept with us—even if it’s just a basic vision of how it should look and work. We will collaborate with you to develop a plan for your product. - Feasibility

To determine if your idea is truly possible, a feasibility study might be required. ETS will conduct targeted experiments to test your concept’s core science and innovations. Our engineers typically breadboard or test circuits to ensure the critical features perform as expected. - Design

Once your concept is proven feasible, the design phase begins. Our engineers specialize in analog, digital, mixed-signal, linear, and power supply systems, and will design your product for both performance and manufacturability. We focus on compact, high-reliability solutions that will streamline the manufacturing process. - Prototype

After finalizing the design, ETS will build PCB and electronic product prototypes in-house. With rapid turnaround times and advanced tools, we provide high-quality prototypes, from printed circuit boards to complete box builds. This phase also includes IC programming, wire assembly, and custom prototype enclosure design. - Redesign

Prototypes often spark new ideas. The redesign phase allows for any necessary adjustments to align the product more closely with your evolving needs. Whether adding features or removing unnecessary elements, we work closely with you to fine-tune the design. - Manufacture

Once the prototype is approved, the product moves into manufacturing. ETS combines advanced automation with skilled manual assembly, ensuring fast, high-quality, cost-effective production. Whether it’s a small or large run, we deliver excellence on every scale.

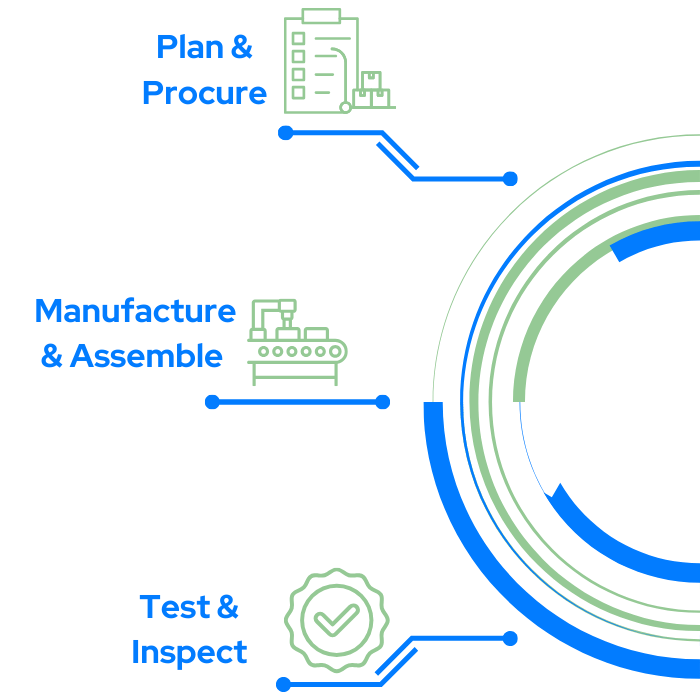

The Production Cycle

The second cycle takes your design through the production phase, ensuring that your product is built to specification, tested for quality, and delivered in a timely manner. Here’s how we handle the production process:

- Plan and Procure

ETS collaborates with you to finalize the production plan, ensuring all specifications are met. We manage the procurement of high-quality materials and components, making sure everything is in place and ready for assembly. - Manufacture and Assemble

Combining automation and manual assembly techniques, ETS manufactures your product with precision and consistency. Our skilled team ensures every part of the assembly process meets the highest quality standards, regardless of the production volume. - Test and Inspect

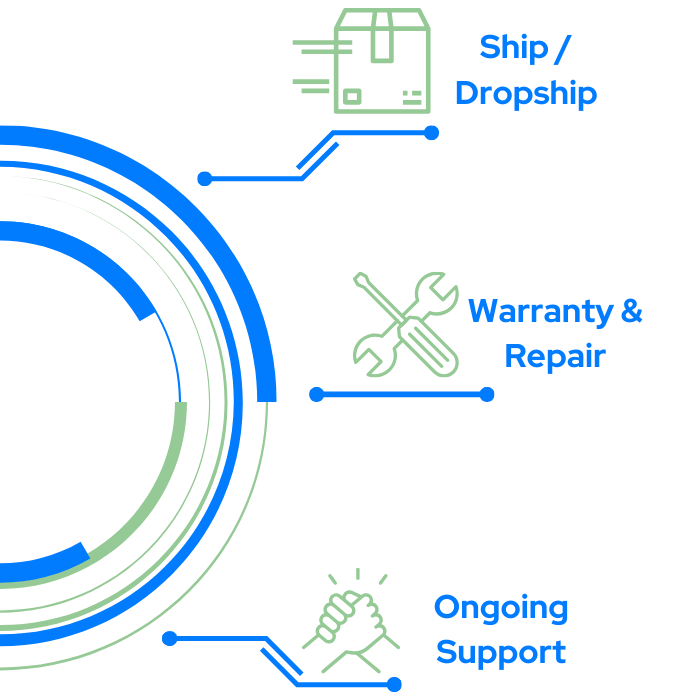

Quality assurance is a priority throughout the production process. ETS performs comprehensive tests at each stage of assembly to ensure the final product meets all customer specifications, industry standards, and reliability requirements. - Ship and Dropship

Once production is complete, ETS ensures your products are carefully packaged for safe delivery. We also offer dropshipping services, allowing products to be sent directly to end customers, saving time and reducing logistics complexity. - Warranty and Repair

If agreed upon, ETS offers warranty support to address any potential issues with your product. Our repair services ensure your products maintain peak performance and longevity, keeping customer satisfaction at the forefront. - Ongoing Support

We believe in long-term partnerships, and provide ongoing support to help you with any updates or modifications your product may need as it evolves. ETS stays in close communication with clients to meet changing requirements and ensure your product’s success over time.

Why Choose ETS for Your Electronics Manufacturing?

- End-to-End Solutions: From the initial concept to final production, we handle every aspect of the manufacturing process.

- Flexibility: We work with both small and large production runs, adjusting to your specific needs.

- Quality Assurance: Our rigorous testing and inspection procedures ensure the highest quality products.

- Cost-Effectiveness: With in-house capabilities and a streamlined process, we provide efficient and affordable manufacturing solutions.

Partner with ETS to bring your ideas to life—our expertise ensures your product not only meets your expectations but exceeds them.

Contact ETS for a Quote!

ETS Production Equipment

ETS Production Equipment

- Juki 750L and Juki 760L fine pitch

Pick and Place Machines. - Quad AVX400 20″ Full Auto

Screen Printer - Heller 1500W 5 Zone, 18″

Convection Reflow Oven - Heller 1500S 18″

Convection Reflow Oven - Manncorp manual 24”

Solder Paste Printer - Soltec 6621 18″ Wave Solder

Machine w/ Spray Fluxer. - 3 CNC Vetrical Milling Machines

for Enclosure Modification and

Panel Manufacturing. - CNC Lathe

- 28 x 24 60Watt laser engraver.

- Gerber Edge II label maker

- Conceptronics Freedom SE

BGA Rework Station - PDR WIC100 X-Ray

Inspection System. - Olamef, APS & Hakko

Component Processors - Electrovert WDC-1 Solder Fountain

- Ideal, Eubanks, & Schleuniger

Wire Processors - Weller WHA 700, Pace SMT-1160

Hot Air Re-Work Stations - Pace and Hakko Solder/De-solder Stations

- LOM II Lead Trimming Saw

- ECD 6300 PCB Board Batch Washer

- ScienceScope inspection system

- Analog Oscilloscopes, DSOs, DMMs,

Spectrum Analyzers, Generators,

Power Supplies, Hi-Pot testers,

Logic Analyzers, Etc. - Band saw, table saw, welding

machines, dill presses, grinders,

sanders, 40″ Combination Sheet

Metal Brake and Shear,

corner notcher

Ready to Work With ETS?

Discover the unparalleled benefits of our Electronics Manufacturing Services. From initial design to final logistics, ETS provides a seamless, full-service solution tailored to meet your specific needs. Our experienced team and technology ensure that every step of your project is executed with precision and excellence. Partner with ETS today and experience the difference in quality and service that sets us apart.

211 Conchas St SE

Albuquerque, New Mexico 87123

United States of America

(505) 888-3923 | sales1@etsnm.com